For convection cells on the sun's surface, see Granule (solar physics).

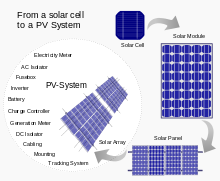

A solar cell, or photovoltaic cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect. It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

Solar cells are described as being photovoltaic irrespective of whether the source is sunlight or an artificial light. They are used as a photodetector (for example infrared detectors), detecting light or other electromagnetic radiation near the visible range, or measuring light intensity.

The operation of a photovoltaic (PV) cell requires 3 basic attributes:

- The absorption of light, generating either electron-hole pairs or excitons.

- The separation of charge carriers of opposite types.

- The separate extraction of those carriers to an external circuit.

In contrast, a solar thermal collector supplies heat by absorbing sunlight, for the purpose of either direct heating or indirect electrical power generation from heat. A "photoelectrolytic cell" (photoelectrochemical cell), on the other hand, refers either to a type of photovoltaic cell (like that developed by Edmond Becquerel and modern dye-sensitized solar cells), or to a device that splits water directly into hydrogen and oxygen using only solar illumination.

Declining costs and breakneck speed

Swanson's law is an observation similar to Moore's Law that states that solar cell prices fall 20% for every doubling of industry capacity. It was featured in an article in the British weekly newspaper The Economist.

Further improvements reduced production costs to under $1 a watt, with wholesale costs well under $2. Balance of system costs were then higher than the panels. Large commercial arrays could be built, as of 2010, at below $3.40 a watt, fully commissioned.

As the semiconductor industry moved to ever-larger boules, older equipment became inexpensive. Cell sizes grew as equipment became available on the surplus market; ARCO Solar's original panels used cells 2 to 4 inches (50 to 100 mm) in diameter. Panels in the 1990s and early 2000s generally used 125 mm wafers; since 2008 almost all new panels use 150 mm cells. The widespread introduction of flat screen televisions in the late 1990s and early 2000s led to the wide availability of large, high-quality glass sheets to cover the panels.

During the 1990s, polysilicon ("poly") cells became increasingly popular. These cells offer less efficiency than their monosilicon ("mono") counterparts, but they are grown in large vats that reduce cost. By the mid-2000s, poly was dominant in the low-cost panel market, but more recently the mono returned to widespread use.

Manufacturers of wafer-based cells responded to high silicon prices in 2004–2008 with rapid reductions in silicon consumption. In 2008, according to Jef Poortmans, director ofIMEC's organic and solar department, current cells use 8–9 grams (0.28–0.32 oz) of silicon per watt of power generation, with wafer thicknesses in the neighborhood of 0.200 mm.

First Solar was briefly the largest panel manufacturer in 2009, using a thin-film CdTe cell sandwiched between two layers of glass.[citation needed] Silicon panels returned to dominance via lower prices, partly from the shift to CHINESE MANUFACTURERS . By late 2011, a drop in European demand due to budgetary turmoil dropped prices for crystalline solar modules to about $1.09 per watt down sharply from 2010. Prices continued to fall in 2012, reaching $0.62/watt by 4Q2012.

. By late 2011, a drop in European demand due to budgetary turmoil dropped prices for crystalline solar modules to about $1.09 per watt down sharply from 2010. Prices continued to fall in 2012, reaching $0.62/watt by 4Q2012.

. By late 2011, a drop in European demand due to budgetary turmoil dropped prices for crystalline solar modules to about $1.09 per watt down sharply from 2010. Prices continued to fall in 2012, reaching $0.62/watt by 4Q2012.

. By late 2011, a drop in European demand due to budgetary turmoil dropped prices for crystalline solar modules to about $1.09 per watt down sharply from 2010. Prices continued to fall in 2012, reaching $0.62/watt by 4Q2012.

Solar power is growing at a breakneck speed. In 2014, the total installed capacity of PV will surpass 150 Gigawatts, up from just 5 gigawatts in 2005.

Multiple solar cells in an integrated group, all oriented in one plane, constitute a solar photovoltaic panel or solar photovoltaic module. Photovoltaic modules often have a sheet of glass on the sun-facing side, allowing light to pass while protecting the semiconductor wafers. Solar cells are usually connected in series in modules, creating an additivevoltage. Connecting cells in parallel yields a higher current; however, problems such as shadow effects can shut down the weaker (less illuminated) parallel string (a number of series connected cells) causing substantial power loss and possible damage because of the reverse bias applied to the shadowed cells by their illuminated partners. Strings of series cells are usually handled independently and not connected in parallel, though (as of 2014) individual power boxes are often supplied for each module, and are connected in parallel. Although modules can be interconnected to create an array with the desired peak DC voltage and loading current capacity, using independent MPPTs (maximum power point trackers) is preferable. Otherwise, shunt diodes can reduce shadowing power loss in arrays with series/parallel connected cells.

No comments:

Post a Comment